Production of bicycles

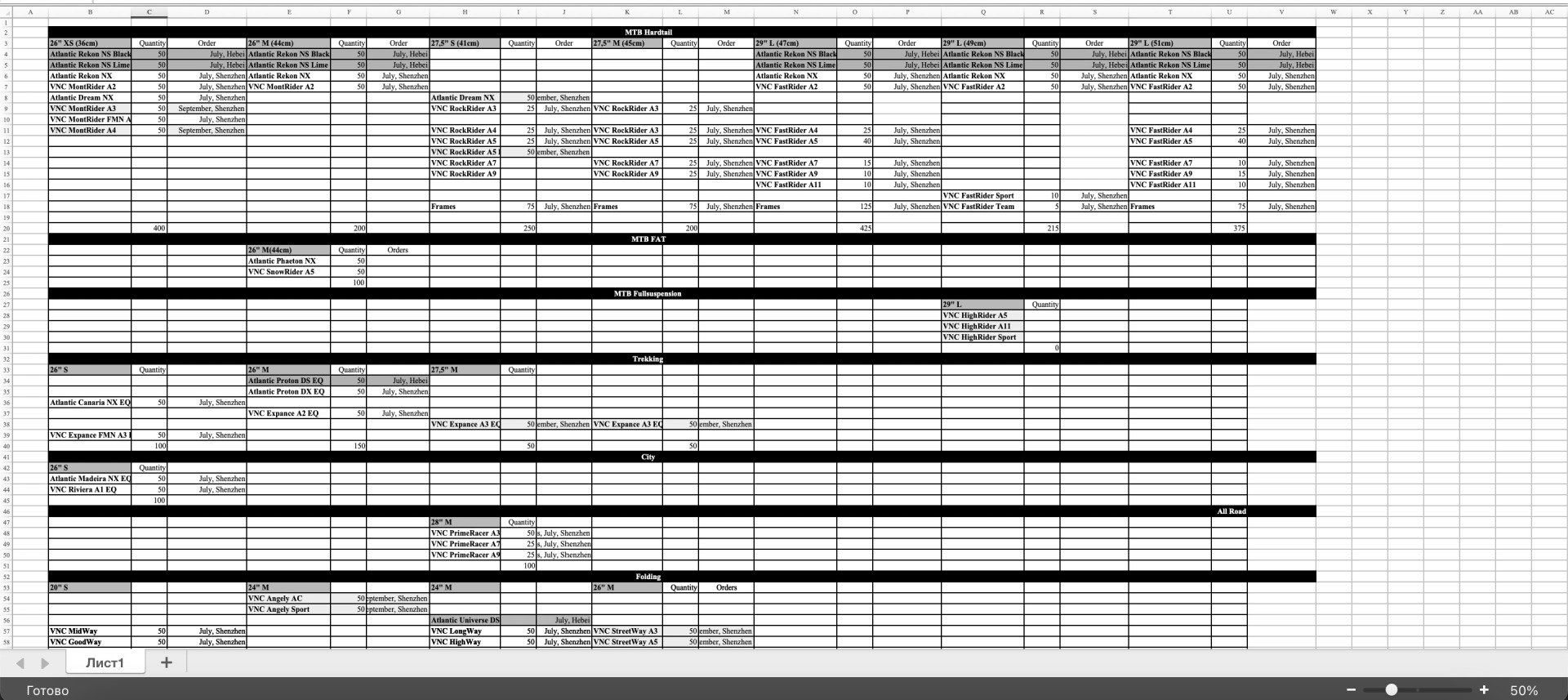

Since 2006, VNC has been a leading bicycle development and manufacturing company. The path to improving production technologies was long and thorny. Bike design takes almost 18 months. This is the path from planning the model range to releasing a ready-made model.

The next step is technical development of the bike. At this stage, we select the components that will make up the bike. Including Shimano and Microshift shift systems, SR Suntour suspension forks, cranks, and other components. VNC uses most of its own V-Class components. Products from Prowheel, Velo saddles, Compass and Wanda tires are also very popular. Maxxis, ChaoYang, brake systems from Logan and Tektro.

Then, logically, the process flows into the next stage. This also includes the production of components, delivery to the factory, where they are assembled and tested with ready-made test samples of bicycles. Each VNC bike model moves to the next stage of mass production if the trial models are successfully tested. You will need to enter the bike specification if you need improvements and other additional changes.

When all 5 stages are completed, bicycles are sent all over the world, where they are looking for their lucky owners. After all, the bikes of our company have high technical characteristics at a reasonable price.